| Home | About | Trains | Yachts | Boats | Maps | Links |

|

|

Major Track Upgrade

by

Keighley and District Model Civil Engineering Society

Click here for most recent news

|

This was the sight that greeted us when we visited Marley railway track for the first time after lockdown. Marley was being used as a Covid 19 testing station so we had special permission to assess what we planned to do while public running was suspended. |

|

Derek brought his theodolite to help the survey. It went in the middle of the first curve and we then took readings to find out how much the track went up and down. |

|

We got into our stride and in week two got down the back straight and then on to the curve behind the bushes where the tunnel used to be. |

|

Week three and we took the readings round by the car park and on to the steaming bay. |

|

The last job was along the station as it started to rain. At least all the measuring was finished for Derek to draw out the track and start to work out what quantities of materials we might need. |

|

Derek and Ian set off round the top curve with a couple of chains dangling from a cross beam on a truck. The grass was spray painted to mark out where the excavator should dig a trench. |

|

All the bolts holding the track down had to be removed so the curve could be dismantled.Colin took a major role supervising the work. |

|

With the bolts undone the track was loosed before being stored away. |

|

Starting to remove sleepers. Most were quite rotten but have gone to good use in people's gardens. |

|

All the first semi circle from the station to the back straight was cleared of sleepers, leaving only the posts in the ground. |

|

Then we had some mechanical help to dig the footings. Many thanks to both Lingfield Services (Cross Roads) and Judsons who kindly undertook the excavation works for the track. |

|

The digger team made light work of clearing the bases and digging the footings. The footings were dug as far as the back straight and some chippings put in the base. |

|

The bridge is constantly being vandalised, so the opportunity is also being taken to make it as sturdy as possible.First thing was to attack with the angle grinder. |

|

Day one saw the first two replacement uprights going in. |

|

Four new uprights were put in along with handrails across the top. Derek is checking the footings for the gradient. The plan is to make it a little easier to get a smooth start away from the station. |

|

Supplies arrived by lorry on a rather hot day. Off loading the concrete beams was easy with the hiab crane. |

|

Next was the plywood for the concrete shuttering. Here there is just the steel mesh for reinforcing the concrete left. |

|

The pegs for the concrete shuttering boards needed a sledge hammer to get them into the ground. |

|

Fixing the plywood shuttering to the pegs. |

|

First piece of shuttering screwed in place. |

|

Day three of the concrete shuttering and we worked on the outer plywood. |

|

Good to have Colin back supervising after his eye operation. Unfortunately he can probably see what we're doing now. |

|

Chris banking the soil up on the outside of the shuttering. We need the ground level with the concrete for the mower. |

|

To provide some hardcore in the bottom of the trench we had a delivery of road scalpings. This is what the pile looked like. |

|

As we were tidying the piles of earth by the track we found another concrete block. Quick work to move it with the mower and sled. |

|

By the end of day five we had made good progress.Probably 2/3 the way round now. |

|

Day six and Derek shuttering the outside curve. |

|

Having to make use of taller boards here. |

|

By end of day six we are nearly there. |

|

Day seven and Theo came down to help move the scrapings. Here he is filling yet another barrow. |

|

At this point the surrounding ground is so low we are starting to need really deep boards. |

|

We did as much as we could to bank the sides up. We are really close now. Just tidying up the ends to do, but we have to stop for LOCKDOWN 2. |

|

It's now February 2021 and we haven't been on site for over 3 months. Its LOCKDOWN 3 so we are all staying at home because that's the law. However, the construction industry is still allowed to work during this third lockdown, so we hired in the people who could work. They tamped down the hardcore scrapings to make it all nice and solid and put ends on the shuttering. They also laid steel reinforcing mesh on top of this. |

| The Concrete lorry had to park in a particular way to get the load up the conveyor belt as the dump truck scoop was so high. 10.5 cubic meters of concrete was to be used - the full wagon load with 1/2 a bucket full left spare. |

| The dumper truck was used to transfer the concrete to the shuttered strip. This was a lot easier than the proposed gang with wheel barrows that we would have done if we had not got the contractors in. The Pour was started from the back straight, furthest away from the lorry. |

| The concrete was levelled up between tips from the dumper truck. You can see the reinforcing mesh here. |

| Here you can see the end shuttering with the concreting finished. The steel reinforcing will tie in to the concrete pour from here to the station. It had taken just 2 hours to do the pour. |

|

This is the end of the day looking from the station. We are now keen to get on. We will now be able to do some measuring and preparation of the pillars. |

| We needed some top soil to bank up the sides of the concrete, so we got a big lorry to deliver some the last week of lockdown 3. |

| First job for recommenced work parties is to spread it out along the sides of the concrete. |

| 5 steel bases were made up and then the concrete sleepers were put on top. A bit of track and a passenger truck and it was all looking pretty good. Ian is providing some ballast as the trucks do go down a bit with weight on them. |

| This is how it will look with the stands, sleepers and track. |

| All the concrete sleepers need to be drilled for fixing to the upright stands. |

| This is join from curve to back straight. |

| Drilling the new uprights for the fixing bolts. We were working between showers so Ian is sheltering in the doorway of his van. |

| Colin then got on with painting them in the clubhouse. |

| We were loaned a digger to spread out the mounds of earth that had been delivered earlier. You can also see the progress with the track bases and concrete sleepers. |

| At last, fixing the track down round the rebuilt curve. |

| Some of the fixing bolts now fouled the cross sleepers in the track so first some new sleepers were welded in. The offending steel sleepers were then cut out. |

| The cross sleepers were then all checked for flatness as some had distorted during their life on the old wooden sleepers.. |

| It was hard work with a pick axe preparing the banked sides for grass seeding. The work that had been done with the digger had now baked hard in the hot weather. |

| The footings for the last bit of concrete to join the curve with the station were also started. |

| When a mounting hole had been drilled in the concrete it then had to be cleaned out thoroughly. First with a bristle brush.... |

| ... then it was blown out with compressed air. |

| A very sticky compound was then injected down the hole. |

| A bolt was then inserted in the goo. When the compound sets it will secure the bolt in the concrete. |

| Gently tightening the bolt in the base. They will be fully tightened when the track is all in position and adjusted for level and cant with the 4 jacking screws that can be seen in the bottom plates of the pillars. |

| Today there was a big effort to prepare the last section ready for a concrete pour. We got shuttering in, added some hardcore to the base and ramped up the sides with the soil. |

| You can see there is just a short gap left before we have the track connected up again. |

| We finished the shuttering for the concrete and refixed the water supply so this is now ready for he concrete pour. |

|

The following Friday the hard core was whacked down and the reinforcing mesh laid as last time. All was then ready, hoping the rain would ease. We had decided to extend the platform both sides of the track at the end of the station to help the steam loco crews. |

|

When the lorry arrived it was all action. There was no option but to get stuck in to the job, hopefully not literally. Fortunately the ground was firmer than last time and the lorry could get on to the site so the concrete went straight in to the prepared shuttering. |

|

It was all neatly finished off in the end, and taped off to deter the inquisitive. |

|

We made new pillars and swapped them out with the old ones to smooth the transition between the curve and the back straight. |

|

We then fixed the track back down. |

|

This is what the transition between the new curve and the back straight now looks like. |

|

Two weeks later and all the supports are in place and the track joined up. Still work to do making the final alignment, but running trains again is in sight. |

|

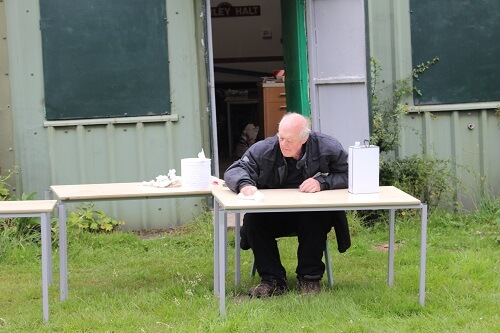

We also made a start on tidying up. First job is cleaning the club house tables before Janette notices ;-). |

|

Well we had to get a loco out. This is the first trial round the new curve. |

|

When we went to check the water supply in the tower we discovered the floor had gone rotten. The tanks came out and a new floor went in. |

|

Having got a complete track again we decided it was time to try things out. We had a running session for club members and some of their children. Here we are getting all the toys out. |

|

This is what it now looks like at the end of the station with trains running. The grass is starting to cover the bare soil. |

|

Plenty of smoke as James raised steam on Charles. |

|

Janette came down of course, and wanted a ride behind anything steam! |

|

With reduced head height under the bridge it was decided we ought to make it a little safer for the loco crews. A preformed sheet of metal was purchased. The next job was to attach it to the underside of the walkway. |

|

There were lots of holes to drill. Then painting and more drilling on the footbridge walk way. |

|

And more painting when the sheet of steel was in place. |

|

With the smoke deflector in place it was time to put on some new railings. |

|

All the handrails done. They just need painting. It looked very smart at the end of the day. You can also see how the grass is growing over the new soil banks. |

Next Step - The Back Straight

We had another club running day on a rather wet Saturday in October 2021. This was prior to starting the next phase of trackwork. Having completed most of the work from the station round the first curve, our attention has turned to the back straight. The wooden sleepers have been in place for many years so we are replacing them with concrete beams. We will also take out the couple of dips caused by the rabbits burrowing under the bases. At the moment there is an incline between the curve and the straight as we transition between the concrete and the current wooden sleepers. The theory is that we can put the incline further down the straight if we want to stop the work and run trains!

|

The Concrete beams are heavy. It takes four men to lift them. |

|

The wooden sleepers we are replacing are not quite the same length, so all the new beams need a little bit trimming off the end. The concrete beam is resting on a couple of modified bogies we are using to transport the beams. |

|

After the first week it was decided to put rubber pads between the concrete beams and the steel bases. Here Colin is drilling holes in the rubber pads. |

|

When drilling the concrete beams it's quite important that the drill is vertical, so the onlookers are not standing idle! Meanwhile, the track is getting fixed down on the concrete beams positioned last week. It was quite a quick job to slip the rubber pads in first so this section is all finished. |

|

Any rails not fixed down are stored in the clubhouse during the week. We had just moved some beams in preparation for the next working party, so used the bogies to take the rails back. |

|

This was not a good day with the rain quite heavy at times. However, we want to get this finished so we can run again, so work carried on in the rain. |

|

There are not many sleepers to replace now, but the rain got too heavy and we had to abandon for the day. |

|

We wanted to run trains over Christmas so the temporary incline idea was put to the test. Here a number of rubber pads are being used as packing pieces under the last couple of concrete sleepers to make a gentle gradient up to the wooden sleepers. Lesson learnt and a jack was used to raise them rather than manually lifting. |

|

This is a view of the temporary transition. Looks like it should work. You can see how near we are to getting this back straight to join up with the concrete sleepers on the curve. |

|

We had a track inspection (passed) by the local robin, though I think he was more interested in the grubs we had disturbed. |

|

Last working party of 2021. We came down to tidy a few things up and make sure all was in order for our private club running session over the Christmas period. However, with the increase of Covid 19 it has been decided to postpone the club running and suspend working parties for the time being. Here moss killer is being applied to the existing concrete sleepers to stop water being held in them which might cause them to break in the freezing winter. |

|

The station is the other are of existing concrete track support, so we cleaned the moss off and sprayed there too. |

|

This picture was taken on December 29th 2019. It was our last public running day, now 2 years ago. Little did we know what might happen a few months later. When I titled this page 'Major Track Upgrade 2020-2021 it was with the thought that we would be running in October 2020, and then work some more over the following winter.

When we are able to continue working the title will no longer reflect the contents of the page. Maybe I should offer a prize for the best new page title of a free ride behind Charles at the first public running day. Look forward to seeing you there anyway. Wishing you all a Happy Christmas and a healthy New Year. Charles' driver. |

|

Lovely and sunny at the start of the final day on back straight. |

|

The last last two piers are original concrete blocks so these needed a bit more work to get the concrete sleepers at the right level. |

|

The concrete sleepers are all lined up and ready for track. |

|

It never goes back together in the same way as it came apart, so here a small adjustment is being made with the angle grinder. |

|

This is the last joint being put together at the end of the long back straight. A few things still need adjustment, but essentially the track is a complete circuit again. |

|

This is the transition between what we have just finished and the next section round the hidden curves.This bit was relaid in concrete sleepers a few years ago, so just over half the circuit now is concrete sleepers. Hopefully this will cut down the maintenance. |

|

There were a number of dips along the back straight that we wanted to look at. At each dip we jacked up the sleepers and put more rubber pads under the joints. |

|

The back straight looks much better now. Any dips and peaks are much more gentle. |

|

The concrete plinth round the first curve was quite expensive to do, so a different plan is being used to provide an anti tilt function here. Shuttering boards have been placed along the back straight at a distance measured down from the track. Scalpings are being laid in between to build up the ground so we have a similar safety platform to the first curve under the track. |

|

We have started work on the bottom curve to reduce the distance from the track to the ground. This is for health and safety reasons. Today we are using a digger at bottom curve to level piles of spoil that we have been accumulating. The truck in the foreground is used to get the track to earthe base uniform and was used to set the shuttering down the back straight. |

|

Filling in under the track had to be done manually with shovels. |

|

This is how the bottom straight looked at the end of the day. There is still a lot of infill needed. |

|

We also used the digger to load scalpings into the new trailer which can be hitched behind the mower. |

|

We are expecting delivery of another container soon. We are having to straighten out the driveway that will run behind it. |

|

Another job has been to remove the fencing from around the track where the model cars used to race. We have an exciting new use for this. All will be revealed in due time. |

|

The third container was delivered and off loaded along side the first two. |

And Now - The Bottom Curve

The track on the bottom curve has always been quite high off the ground. As a major reason for these works is to improve safety we have decided to build up the soil level around the track so we can eventually do something similar to the back straight. It will take a while for the soil to settle, (maybe a couple of years,) so this is a long term project.

|

We received a grant to improve the area surrounding the track, so we used that to hire some extra help in the way of mechanisation. There was a pile of earth delivered in a big truck and here it is being transferred to a trailer to get it to the track. |

|

This is what it started to look like after the first loads of earth had been brought from the big pile. |

|

The area we are working on is all the way from the river curve to just beyond the swing bridge. |

|

Derek and Colin drove the trailer back and forth and unloaded next to the track. |

|

The ground was very wet and soft which is why a car and trailer was used rather than bringing a big truck. These are the wheel ruts after just a few trips. |

|

The digger did venture up to the track to level off the piles of earth that had been off loaded. |

|

So some took the opportunity for a tea break. |

|

And here's looking from the other direction. |

|

After the levelling it looks much better. |

|

We did have to refix some of the track and clean all the mud off. |

|

We also managed to finish off the back straight shuttering.The box in the foreground is shuttering for a signal base as part of a signalling project. |

|

The next few pictures are as far as we got by the end of November when we stopped to let things settle for a while. Here we are looking back from the end of the locomotive loading siding. |

|

Here we are looking backwards from the swing bridge that goes to the middle of the track. |

|

Again looking backwards, towards the bottom straight. |

|

Looking forwards from the curve by the river at the end of 2022. |

|

In January 2023 a final push was started to replace the remaining wooden sleepers with concrete ones. For a change we worked anticlockwise, so the first sleepers to be replaced were by the swing bridge. Here we are looking backwards from the swing bridge towards the station. |

|

Here we are looking the other way, backwards round the track from the swing bridge that goes to the middle of the track. The first few sleepers are in place waiting for the track to go back on. |

|

Because the wooden sleepers were bolted at the ends with overlapping plates we can change our method of replacement here, which will make things much quicker. You can just about see metal plates spaced above the concrete piers which the new sleepers rest on. (The new sleepers are thinner than the old wooden ones.) By using jacking screws we can level the concrete sleepers quite easily after they are in place. |

|

Here we are looking the usual way round. We started using the rubber pads on back straight so hopefully this will give us a quieter and smoother ride here as well. |

|

A few weeks later the track was back on and the new concrete sleepers are along the straight. |

|

The track needed some careful adjustment. |

|

From the end of the concrete sleepers you can see the pads and adjusters along the next pillars. |

|

Here the metal plates that the concrete sleeper will rest on are being adjusted for height. |

|

The 4 bolts means the plate can also be adjusted to get it level. |

|

Then the 0.4 gradient that is required for this section can be put in. |

|

Further along this is the fiddly job of getting the centre location bolt in the old concrete pillars. |

|

Always easier with two. Colin doing what he does best. We'll miss him. |

|

This is down by the river curve. There's still a bit of a gap before we can run trains again. |

|

It's a long way to take the new sleepers, so they were balanced on the bogies we have used before. |

|

This is how well we've done by the end of February. |

|

The first Saturday working party in March saw the last mounting plate going in. |

|

There are now only 3 sleepers left to put in to complete the circuit. This is the section down by the river bank. |

|

Then we can put the remaining 3 sections of track back in and run trains again. |

|

This week, the last concrete sleeper has just been put in place. |

|

You can just see the end of the concrete sleepers that were put in a few years ago, so we nearly have concrete sleepers round the whole circuit. |

|

The remaining 3 sections of track were then put back in. |

|

We had found when working on the first curve that the some of the steel sleeper ties had bent when tightened on to the wood sleepers, so for all the new sections they were straightened out before bolting down again. This is the very last piece to do. |

|

Inevitably the track did not join up exactly. The gap was small but easiest done with a section a couple of feet long. Here the gap and filler piece are being cut to size. |

|

To hold the track together some ears need to be welded on. This is best done off site, so unfortunately there was no test train today. |

|

This is the view in March 2023 from the end of the work that had been done over the winter. |

|

This is the bottom straight. All the people walking about has nicely compacted the earth banking as well! |

|

This is a view of the bottom straight looking back round the track. |

|

Again looking back round the track to show the bridge where these winter works started from. |

|

This view from the bridge to the steaming area shows the final section that is left of the old wooden sleepers. |

Last section - Winter 2023-24

The remaining section of wooden sleepers on the running line is due for replacement over the winter of 2023/24. This is to be done in two stages so the track will be useable for the Christmas Mince Pie Special. We will work backwards from the concrete block wall leading up to the turntables.

|

First a recap on the year 2023. The carriage siding leading from the turntable was replaced with a concrete beam and extended so that we can have the carriages ready to put on the line behind locos coming from the steaming bay. |

|

Your intrepid reporter wasn't able to make the first couple of working parties, so by the time he got down the straight section had all the wooden sleepers removed and replaced with the concrete beams. |

|

So the routine of removing sleepers a few at a time and cutting new concrete beams to length continued around the 'S' bend. We were now on different upright bases so a lot more packing would be needed. |

|

Here's the messy and noisy job of cutting beams, which is why it's a distant shot. |

|

Here we have the last couple of concrete beams to go in around the 'S' bend. |

|

It was -5 degrees when we turned up today. Such is our dedication to provide train rides for you all. The track has to be all back in place for the 'Mince Pie Special' at Christmas. |

|

It was going to be a big effort to get all the track on the beams and at least in position. |

|

There was still some final levelling between the beams with various packing pieces. |

|

There was one beam where the concrete had not poured well. We decided it was better and easier to replace it now than have it fail in a couple of years. |

|

When we started on this track upgrade several years ago, we discovered that bolting the track down to wooden sleepers had bowed the metal ties between the rails. As we have relaid the track on supposedly flat concrete beams the opportunity has been taken to make the fine adjustment to make them straight again. |

|

Science lesson now. When steel gets warm it expands. As it was still freezing cold the rails were at their shortest, and in the summer they would be longer. To allow for the extra length in the summer we needed to allow a gap. We put in shims while putting the track together to allow for this which we took out after the rails were fixed down. All scientifically calculated of course. |

|

So all back together again. A few more bolts to go in and there is a bit of a level difference between this section and the wooden sleepers up to the bridge, but we should be OK again for Christmas. |

|

A weekday working party saw the transition between the new section and the remaining wooden sleepers made good. All ready for the next public running. |

|

We had to get a loco out and try it out of course. |

|

The opportunity was taken to do a spot of truck maintenance as well. |

|

The New Year and it was back to the civil engineering again. Ian is painting more base plates. There are some already done on the table behind him. Our most important worker is Bill who makes us tea and coffee. He is hiding out of shot to the right. |

|

It is critical that the swing bridge lines up with the section of track we are replacing. Opportunity is being taken to replace the worn out wheels with new ones. They are the 4 on the 'U' section on the ground. The old wheels are being removed with a grinder. |

|

Looking towards what we did before Christmas, the remaining wooded sleepers have now been removed. |

|

The next job was to cut even more concrete sleepers to fit the gaps where the wooden sleepers had been. |

|

New bridge wheels in position and welded in place. |

|

Bridge support being fitted to new concrete sleepers. |

|

Looking from the bridge towards station. |

|

Looking backwards round the track towards the bridge. |

|

Bridge end support grinding before welding. |

|

This winter's effort of sleeper replacement. |

|

A pipe was laid across the field and a new stand made so that we can have water for traction engine next to where it runs. |

Webtrains by Mike Badger

This page

was last updated on Saturday 10th February 2024 at 20:00.